Pressure signals

by Ric Tester

Australian Shooter May 2002

With increasing numbers of shooters engaging in handloading, it is always a worthwhile exercise to examine the effects and possible consequences of improper reloading procedures. The handloader, unfortunately, often fails to appreciate the potential for calamity should he or she make an error or misjudgment in the construction of a cartridge.

While good handloaded cartridges can be accurate, economical and tailored to suit a special need, there can be a downside. An incorrectly constructed cartridge can destroy a gun and cause serious injury. As with all issues involving firearms, handloading must be carried out with the appropriate measure of caution, attention to safety and above all - common sense. The enemies of the intelligent handloader include assumption, guesswork, sloppiness and ignorance, since any mix of these could have unfortunate consequences. This article discusses the creation and management of chamber pressure, that necessary evil that needs to be understood by all who desire to understand the nature of guns.

While good handloaded cartridges can be accurate, economical and tailored to suit a special need, there can be a downside. An incorrectly constructed cartridge can destroy a gun and cause serious injury. As with all issues involving firearms, handloading must be carried out with the appropriate measure of caution, attention to safety and above all - common sense. The enemies of the intelligent handloader include assumption, guesswork, sloppiness and ignorance, since any mix of these could have unfortunate consequences. This article discusses the creation and management of chamber pressure, that necessary evil that needs to be understood by all who desire to understand the nature of guns.

What causes chamber pressure?

At the time of firing, the propellant (smokeless

or black powder) will burn very rapidly and produce a great deal of hot

gas. This gas, being enclosed in a cartridge case, is in a highly compressed

state and according to the laws of physics, will exert enormous pressure

on everything around it in order to expand its volume. Chamber pressure

in a rifle - typically many thousands of times the normal atmospheric

pressure - will not only expand the cartridge case and press it hard against

the chamber wall, but will accelerate the projectile through the length

of the barrel, imparting to it a suitable level of velocity and energy

for the job at hand. In most cases, rifles operate at a much higher chamber

pressure than handguns or shotguns and consequently need to be constructed

accordingly. The rate at which a powder burns will have a profound influence

upon pressure. Generally speaking, a powder that burns slowly will release

gas at a steady rate, resulting in a gradual increase in pressure until

‘peak pressure’ is attained. A faster burning powder will release gas

quickly and reach peak pressure in a much shorter interval of time. Chamber

pressure will of course be released when the projectile exits the barrel.

Some, but not all, reloading manuals will indicate an industry operating pressure for a particular calibre. This may be presented as either a value in ‘copper units of pressure’ (c.u.p) or pounds per square inch (psi), depending upon how the measurement was obtained.

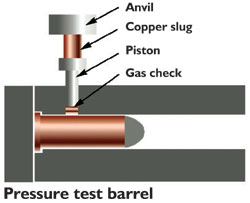

The former value (also the oldest) is established by placing the cartridge in a special barrel that has been fitted with a piston located directly above the combustion chamber. Upon firing, the expanding gases will drive the piston into a slug of copper whose dimensions and metallurgy are accurately known. The degree of deformation of the slug may then be measured and the change is referenced against an index chart from where the value for the c.u.p can be obtained. A more modern method of measuring pressure is to install a transducer into the chamber wall. The transducer contains a small crystal that will deform slightly when under pressure and release a small quantity of electric current. The greater the pressure, the greater the current. Upon firing, the current is fed directly into a computer that will automatically calculate and display pressure readout in psi. The guns that are used to determine pressure are loaded with reference ammunition that has been manufactured and loaded to exacting standards.

How much is enough?

The performance and reliability of firearms has improved notably in the past 100 years. Improved manufacturing techniques and better alloys have permitted much higher chamber pressures and, consequently, remarkable increases in velocity and energy. The .458 Winchester Magnum, for example, is able to equal or surpass several of the huge, antiquated British elephant cartridges in ballistic performance. The .416 Remington Magnum, introduced in 1988, delivers similar performance to the old .416 Rigby - in a much smaller cartridge.

The authors of reloading manuals are considerate of both performance and safety and their reloading data has been obtained through thorough research and extensive testing. The recommended powder types and loads for the various calibres have been calculated to produce good performance at safe pressure levels. The published ‘maximum load’ should always be approached with caution and must never be exceeded.

The dangers of excessive pressure

The dangers of excessive pressure

Any situation involving excessive pressure is potentially dangerous. Firearm manufacturers will always produce guns with an inbuilt safety factor. A careless reload, however, can easily exceed the most generous tolerance, destroying the gun and possibly injuring shooters or bystanders. Firearms that have been thrashed with heavy or ‘hot’ loads during their lifetime will almost always give out before those that have not. Heavy loads that result in elevated pressures will loosen up the clockwork of revolvers relatively quickly. Barrels can be fouled by bullet shavings from projectiles that have been driven down them at higher-than-recommended velocities. Cartridge cases will quickly succumb to the hammering they receive when chamber pressure is up. Quite obviously, there are simply no virtues to be found in a high-pressure situation.

The signals that may indicate high pressure

Difficulty in extracting a fired case is a prime indication of excessive chamber pressure. When a case has been expanded against the chamber wall it may hold tight, making withdrawal difficult. In an extreme case, the bolt may need to be hammered open. If the muzzle blast was unusually loud or the recoil was greater than normal, this would support the hypothesis of the existence of high pressure. Often, the case head will reveal a high-pressure situation by showing a shiny mark where the metal of the head has flowed into the ejector recess of the bolt face. This is one of the most definitive indications of pressure.

Examination of primers is another important factor in the determination of excessive pressure. If the primer pockets are loose, allowing the easy seating of new primers, this can be pressure related. This is especially true if it is followed by gas leakage around the primer - often illustrated by the appearance of a black sooty residue around the outside perimeter. Cases, which have been damaged in this way, must be discarded and the loads reduced.

A flattened primer is also another possible indicator of a high-pressure situation, but in the absence of other factors, this one symptom could be indicative of a case that has been badly resized. A crater-like appearance of the primer after firing may also suggest that everything is not okay in the pressure department. While cratering can be indicative of a worn firing pin, heavy cratering is, again, regarded as a sign of undue pressure. If the cases have a short life, the reloader would also be justified in suspecting high pressure.

In extreme cases of high pressure, primers can be completely pierced or blown. Cases may suffer deformation - usually in the form of case head expansion or even complete destruction. Finally, the chamber itself can yield to a massive rise in pressure and crack up. Such instances are (thankfully) not common, but are not unknown. The risk of personal injury in such a situation is high and this fact alone validates the necessity to wear the appropriate eye protection at all times while shooting.

What factors may bring about excessive pressure?

Physical laws dictate that gas expands when

it is heated. If the gas is held in a fixed space and heated, the pressure

will increase. A normal load at room temperature may show signs of pressure

in an ambient temperature of, say, 40 degrees. It is also understood that

some powders known as ‘double base’ powders may produce dangerous pressures

if fired in conditions of extreme cold.

One of the most frequent causes of high pressure is using too much powder in an effort to squeeze from the cartridge that last few feet per second in velocity. Sometimes an overload of only a few percent is sufficient to send pressure values through the roof.

Large capacity rifle cases generally use a slower burning powder. The reloader must be careful not to place a charge that is lower than the recommended minimum, as this can result in a ‘hang fire’ with associated high pressures. There are a number of theories on how a reduced load can cause an elevation in pressure, but suffice to say, we know that it can occur and should act accordingly.

Another well-known cause of cartridge blow-ups and stuck bolts is the use of incorrect powder. A fast burning powder will release its energy quickly and its deliberate or accidental use can have severe consequences. There have been a number of documented cases where fast-burning pistol powders have been used in rifle cartridges - with predictable results (ie, one blown up rifle).

Chamber pressure can also be driven up if the bullet meets an obstruction during its journey down the barrel. Grease, rust, a stuck bullet, a cleaning patch or water may keep the lid on the pot long enough for the pressure to rise and do damage. The muzzle of a gun must never be held under water before being fired.

Chamber pressure can also be driven up if the bullet meets an obstruction during its journey down the barrel. Grease, rust, a stuck bullet, a cleaning patch or water may keep the lid on the pot long enough for the pressure to rise and do damage. The muzzle of a gun must never be held under water before being fired.

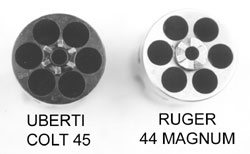

A bullet that is too large in diameter for the barrel can be another cause of escalating pressures. A .44-40 shell for example, which takes a bullet of diameter 0.426 inches, must never ever be loaded with a projectile intended for .44 magnum, which has a nominal diameter of 0.429 or 0.430 inches. The increased pressure due to the larger bullet trying to squeeze its way down the barrel will again precipitate an unsafe situation.

While on the subject of bullets, the seating depth can also influence pressure. A bullet that is seated too far into the case may confine the powder too much, which would cause a serious rise in pressure upon firing. If the bullet is seated too far out, it may contact the lands of the rifling, which again would act as an obstruction. Upon firing, the bullet, rather than moving forward and getting a ‘running jump’ at the rifling, would be hard up against it and may not be able to move until the chamber pressure was already alarmingly high.

A bullet, which has a large bearing surface, may not be able to be substituted for another whose bearing surface is small. The increased surface area in contact with the barrel may again force pressure up. It is not generally acceptable when reloading to replace a bullet with another of greater mass. The heavier bullet will have more inertia (resistance to movement) and will cause a rise in pressure.

A bullet that is heavily crimped in place will require substantial pressure in order to break free from the case. Heavy crimps can increase pressure. A cartridge case that has not been trimmed to size may crimp the bullet in place when a rifle bolt is locked. The camming action of the bolt can apply a substantial force, creating a crimp that requires extreme pressure to breach. The thickness of the case neck, if excessive, can have a high friction hold on a bullet that can require a high pressure to shift.

The use of a magnum primer will also be a factor in elevating the chamber pressure. Only use magnum primers in accordance with the instructions provided by the manufacturer and/or the reloading manual.

Low pressure

Some shooters opt to ‘load down’ their cartridges. There are many reasons for this. A cowboy action shooter may load his single action .44 magnum with small charges sufficient for his sport or the owner of a heavy calibre magnum rifle who spends a lot of time at the range may use light loads in order to cut down on recoil and to increase case life. Reloading manuals will generally have entries for reduced loads and these should be followed. Going too low may result in a friction-jammed projectile halfway down the barrel. Should the shooter be unaware of the obstruction and proceed to fire another shot, the firearm/shooter may suffer damage. Remember that the gear has been made to accept certain pressures and there is absolutely no harm in using it for the purpose for which it was intended.

Playing it safe

Always work up your loads gradually and watch for the signs of pressure. Should one or more signs begin to appear and it is likely that your load may be approaching a maximum limit, go no further. Remember that your best load is your most accurate load and choose your calibre for the job at hand. It is a good rule not to accept handloaded ammunition from an unknown origin. You are responsible for your own safety and that especially includes what you choose to put in the chamber of your firearm.

Get into the habit of inspecting cases and primers and recognising the appearance of an ‘acceptable’ load and a ‘hot’ load. Take no shortcuts during your own reloading; make your own ammunition the best ammunition possible for your valuable investment. Remember that pressure is the essence of firearm operation and that it can be both a faithful servant and a cruel master. Learn to recognise the signals of high pressure - read them or weep.